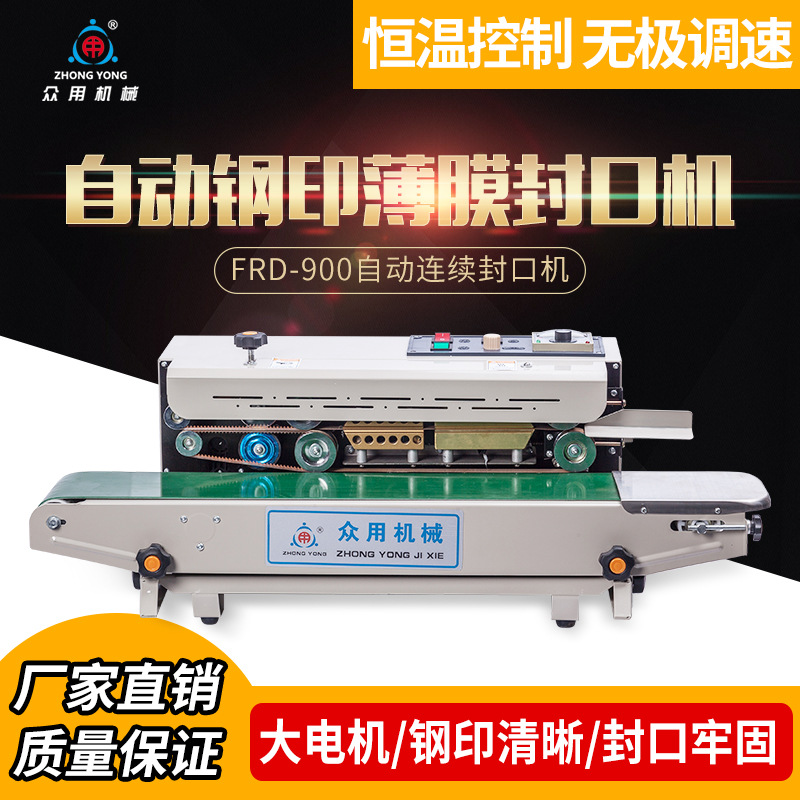

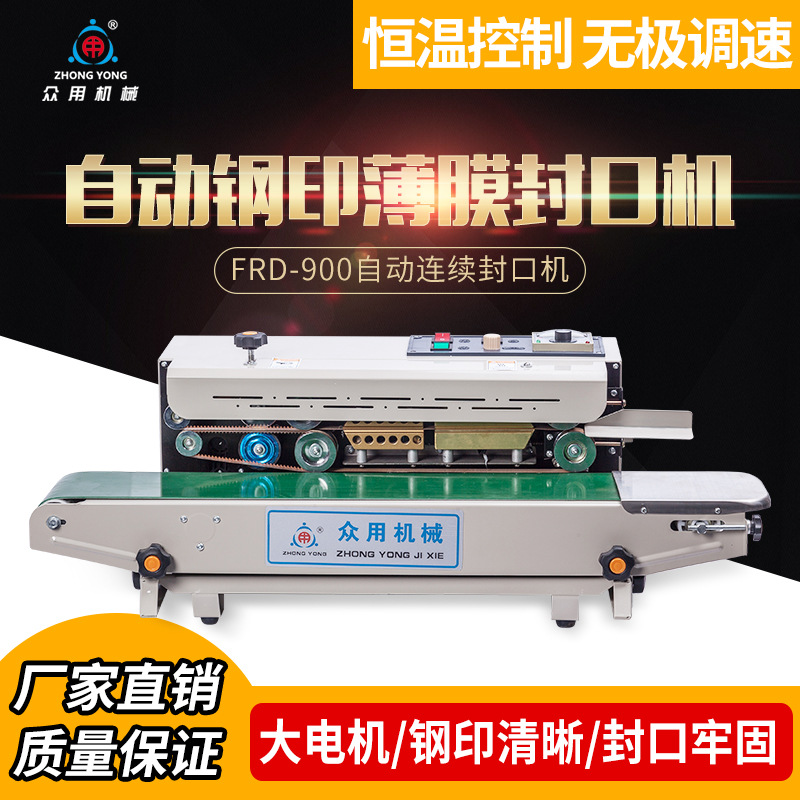

The FR-900 Sealing Machine is a cutting-edge solution designed to streamline the sealing process for various types of packages. This continuous sealing machine boasts impressive specifications that cater to high-performance demands across multiple industries. With features such as adjustable temperature controls and compatibility with numerous packaging materials, the FR-900 stands out as an essential tool for businesses looking to enhance their production efficiency.

Emphasizing user-friendly design and ergonomics, the FR-900 ensures ease of operation while maintaining superior functionality. Its intuitive control panel allows operators to make quick adjustments effortlessly, reducing downtime and enhancing productivity. Every element of the machine's design has been carefully considered to offer unmatched comfort and usability, even during prolonged usage periods.

Versatility in Packaging Applications

The flexibility of the FR-900 makes it suitable for a wide range of packaging applications. Its proficiency in food industry packaging helps preserve product freshness, making it ideal for sealing plastic bags, aluminum foil bags, tea bags, and auto-sealing masks. The pharmaceutical sector can also benefit significantly from the FR-900's precise sealing abilities, ensuring drug safety and shelf stability. Moreover, industrial and retail products find reliable solutions with this machine, adaptable to different material types and packaging requirements.

Advanced Sealing Technology

At the heart of the FR-900 is its advanced continuous sealing mechanism. By providing consistent seals without interruption, it optimizes throughput and minimizes waste. Offering adjustable temperature and speed controls, users can tailor the machine settings to suit specific packaging needs, guaranteeing optimal seal integrity. Importantly, the FR-900 exhibits compatibility with diverse bag materials including plastic and aluminum foil, broadening its scope of application across industries.

Additional Functionalities

The machine extends beyond simple sealing functions. Integrated date coding and batch number printing options allow for effective tracking and traceability of packaged goods. Designed to work seamlessly with conveyor systems, the FR-900 can be easily incorporated into automated production lines. Furthermore, customizable sealing widths and patterns grant businesses greater flexibility in meeting unique packaging requirements.

Efficiency and Productivity

For organizations seeking to boost operational efficiency, the FR-900 presents an attractive proposition. It delivers high-speed sealing, enhancing production capacity and allowing for quicker turnaround times. Not only does the machine require minimal maintenance, but it also supports energy-efficient operations, contributing to cost savings and sustainability efforts.

Safety and Compliance Features

Sustainability in performance doesn't come at the expense of safety. Engineered with built-in safety mechanisms, the FR-900 mitigates risks associated with high-speed machinery. Additionally, it complies with stringent industry standards and regulations, particularly crucial for applications within the food and pharmaceutical sectors. Featuring a hygienic design, the machine guarantees cleanliness and prevents contamination.

User Experience and Ease of Operation

A standout feature of the FR-900 is its emphasis on user experience. An intuitive control panel simplifies setup and adjustment processes, reducing training time for new operators. Coupled with accessible troubleshooting resources and support, users can rely on comprehensive assistance when needed, facilitating smooth and uninterrupted operations.

Real-world Applications and Case Studies

The versatility of the FR-900 shines through in numerous real-world scenarios. Food packaging companies have lauded its ability to maintain product integrity and freshness, evidenced by several success stories. In the pharmaceutical sphere, the machine's precision and reliability underpin critical packaging activities. Testimonials from various industries attest to the FR-900’s effectiveness, highlighting marked improvements in production workflows.

Tips for Optimal Performance

To maximize the longevity and performance of the FR-900, regular maintenance and cleaning are paramount. Following best practices tailored to the type of material being used ensures consistent results. Proper calibration and timely adjustments prevent operational hiccups, securing seamless production cycles.

Future Innovations and Upgrades

As technology evolves, so too will the features of the FR-900. Anticipated enhancements include integration with smart packaging solutions and additional automation capabilities. Keeping abreast of these trends ensures users stay ahead of the curve, leveraging state-of-the-art technologies to maintain competitive edges in their respective markets.

Purchasing and Support Information

Customers interested in acquiring the FR-900 can do so through verified distributors, ensuring they receive genuine products backed by warranties. Comprehensive training modules and resource access further facilitate a smooth onboarding process for new users, empowering them with the knowledge needed to capitalize fully on this exceptional sealing machine.

With an extensive blend of functionality, adaptability, and robust construction, the FR-900 Sealing Machine emerges as a valuable asset for any business involved in packaging. Explore its myriad benefits today and embrace a future of enhanced productivity and unrivaled efficiency.