When it comes to reliable and efficient sealing solutions, the FR-900 automatic sealing machine from Yiwu Zhonghao Machinery Co., LTD stands out as a top choice. This continuous sealing machine is designed for versatile use, capable of sealing aluminum foil bags, plastic bags, tea bags, and masks. Here’s an in-depth look at how you can get the best out of your FR-900 model.

Understanding the FR-900 Automatic Sealing Machine

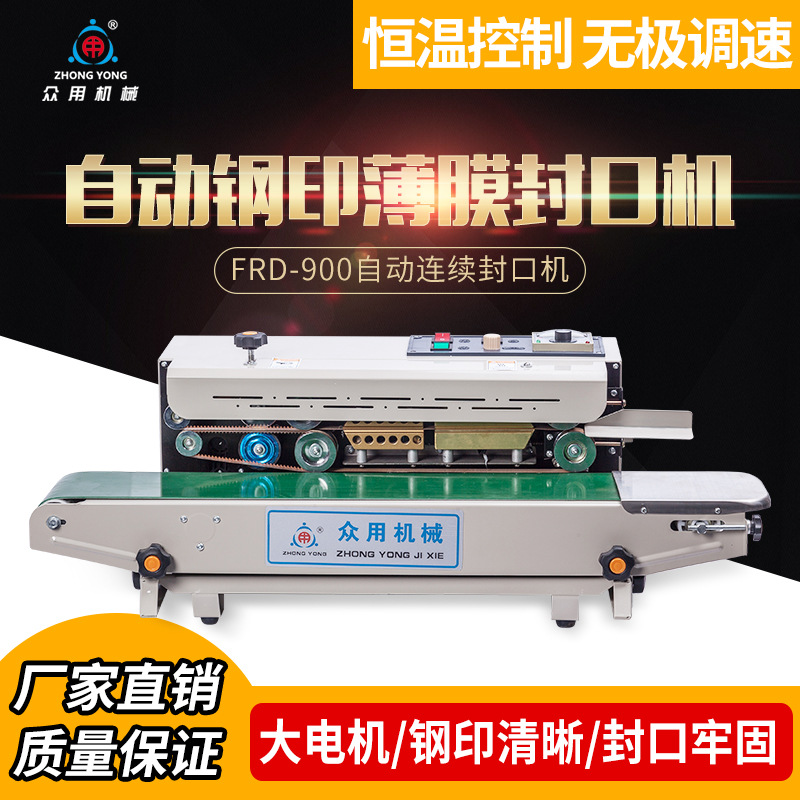

The FR-900 is engineered to make sealing operations straightforward. It boasts several key features including adjustable temperature controls, variable speed settings, and compatibility with various bag materials. The specifications reveal why it's highly regarded: it supports different types of films and offers robust performance suitable for both small-scale packaging and larger industrial tasks.

One significant advantage of using the FR-900 is its efficiency in producing consistent seals, reducing material waste, and speeding up productivity. Its user-friendly design ensures that even those new to sealing machinery find it easy to operate.

Unpacking and Setting Up

Your FR-900 will arrive neatly packed, containing all necessary components such as the main body, conveyor belt, power cable, and instruction manual. Ensuring everything is accounted for, begin by assembling the machine according to the instructions provided. Positioning the machine correctly within your workspace is crucial; it should be placed on a flat, stable surface to avoid any operational disruptions.

Preparing for Operation

First, connect the machine to a suitable power source. Familiarize yourself with the control panel where you’ll set the temperature and speed. Calibration might be required depending on the type of material being sealed. Always follow safety precautions such as wearing protective gear and keeping hands clear of moving parts to avoid accidents.

Types of Bags Compatible with the FR-900

The FR-900 shines in its versatility. It handles film bags efficiently, sealing without compromising the contents. Aluminum foil bags are also well-suited, ideal for products requiring enhanced preservation. Additionally, paper-plastic composite bags and other materials fall within its compatible range, expanding your operational capabilities immensely.

Step-by-Step Sealing Process

Begin by pre-heating the machine to the desired temperature setting suitable for your bag material. Once ready, insert the bag into the designated sealing area while ensuring proper alignment. Adjust the sealing width if needed to cater to different bag sizes. Monitor the process closely to ensure consistency in quality, making fine adjustments as needed.

Troubleshooting Common Issues

If you encounter inconsistent seal quality, first check the temperature settings and alignment of the bags. Jamming or misfeeds may occur due to improper feeding angles or debris—ensure regular cleaning to mitigate this. Overheating problems usually arise from prolonged use; give the machine periodic breaks to cool down and inspect for underlying issues.

Maintenance and Care

Maintaining the FR-900 involves routine cleaning, keeping the sealing surfaces free from residue build-up. Lubrication of moving parts prolongs the machine's lifespan, and timely part replacements prevent unexpected downtimes. When not in use, store the machine in a dry, dust-free environment to maintain its condition.

Tips for Optimizing Sealing Performance

Select appropriate temperature and speed settings relative to the material thickness for optimal results. Ensure each bag is positioned correctly before sealing to avoid misalignment. For enhancing seal strength and durability, consider doubling the seal line for critical applications which require extra security.

Real-World Applications and Use Cases

The FR-900 excels in diverse scenarios, from small-scale artisan food packaging to large commercial bottling facilities. Several businesses have reported improved operational efficiency and product shelf-life after integrating this sealer. Case studies highlight its efficacy in sectors like pharmaceuticals, cosmetics, and food processing industries.

Frequently Asked Questions (FAQs)

Q: How do I know the right temperature for my bags?

A: Refer to the material guidelines often provided by the manufacturer and conduct test runs to fine-tune your settings.

Q: Can the FR-900 seal very thick bags?

A: Yes, but adjustments to temperature and pressure settings are essential to accommodate thicker materials.

Q: What should I do if the machine stops working mid-operation?

A: Check for common issues like overheating, power supply interruptions, or internal component malfunctions and address accordingly.

For more detailed support and additional resources, visiting the official website or contacting technical support provides further assistance.