Understanding the FR-900 Automatic Sealing Machine

Overview of the FR-900

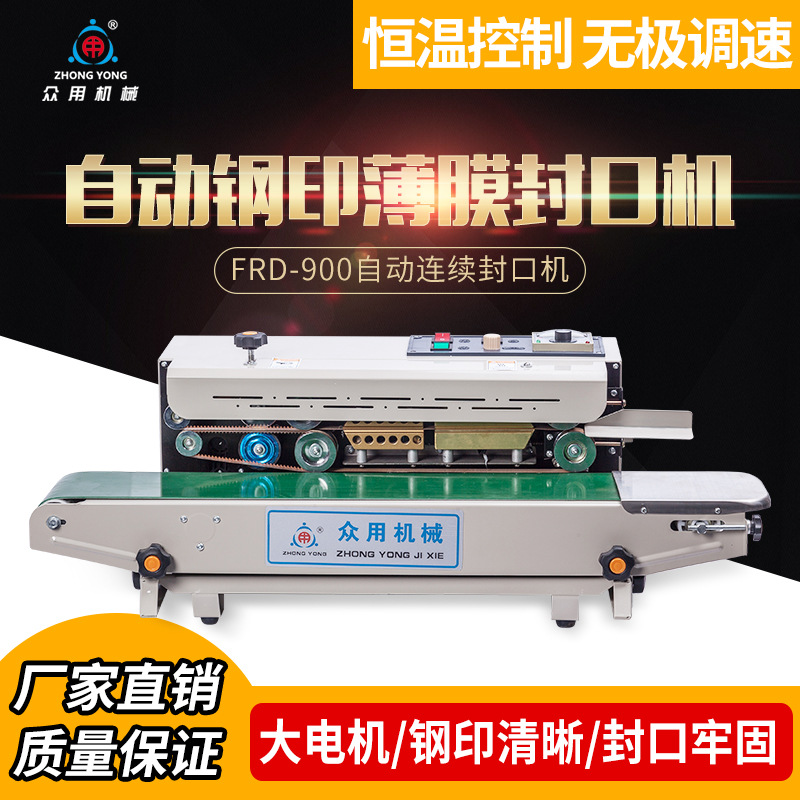

The FR-900 continuous sealing machine by Yiwu Zhonghao Machinery Co., LTD is designed to provide efficient and reliable sealing solutions. It handles various packaging types including film, aluminum foil bags, plastic bags, tea bags, and automatic mask sealing.

Key Components and Design Features

This machine boasts a well-thought-out design featuring sturdy construction, made to endure constant use. Key components include an adjustable speed control, temperature regulation, digital display with a user interface, and a robust conveyor belt system.

Types of Packaging it Handles

The versatility of the FR-900 allows it to handle different materials ranging from delicate plastic films to more durable aluminum foils. This adaptability makes it ideal for a plethora of industries such as food packaging, pharmaceuticals, and industrial applications.

Features of the FR-900 Automatic Sealing Machine

Adjustable Speed Control

The FR-900 features adjustable speed settings that can be fine-tuned according to your production needs, ensuring optimal sealing regardless of workflow requirements.

Temperature Regulation

Consistent sealing quality is achieved through precise temperature regulation, which can be adjusted based on the material being sealed, preventing over or under-heating.

Digital Display and User Interface

A straightforward digital display along with an intuitive user interface makes operating this machine hassle-free, even for those who may not have extensive technical expertise.

Conveyor Belt System

A durable conveyor belt system ensures smooth and consistent movement of packaging materials, minimizing jams and enhancing productivity rates across batch processes.

Versatility in Packaging Materials

From lightweight plastics to heavier aluminum foil bags, the FR-900’s adaptable nature allows it to efficiently seal a variety of packaging materials, making it indispensable in diverse settings.

Benefits of Using the FR-900

Enhanced Efficiency and Productivity

The FR-900's quick setup and easy operation translate into significant time savings, leading to enhanced overall efficiency and higher output levels.

Consistent and Reliable Sealing

Thanks to its precise controls, this machine offers dependable and uniform sealing results, crucial for maintaining product quality and shelf life.

Reduction in Labor Costs

Automating the sealing process reduces manual labor requirements, thereby cutting down labor costs and potential human error.

Versatile Applications Across Industries

From packing snacks to securing pharmaceutical products, the FR-900 serves multiple sectors effectively, highlighting its broad applicability and practicality.

Durability and Low Maintenance

Built for long-term use, the FR-900 requires minimal maintenance, thus offering durability without frequent interruptions for repairs.

Step-by-Step Guide to Operating the FR-900

Setting up the Machine

Unboxing and Initial Assembly: Begin by unboxing all components and following the provided instructions for assembly. Ensure you check each part against the included list to confirm nothing is missing.

Connecting to Power Supply: Once assembled, connect the machine to an appropriate power supply using the designated socket and ensure it's securely plugged in before powering on.

Adjusting Settings for Different Materials

Speed Adjustments: Fine-tune the adjustable speed knob or buttons on the digital interface to suit the thickness and type of material you'll be sealing.

Temperature Settings: Set the correct temperature using the numeric displays to match the requirements of your specific packaging materials for optimal sealing.

Loading and Sealing Process

Positioning the Packaging: Carefully position your package on the conveyor belt, aligning it so the seam meets the heating element correctly.

Running a Test Seal: Before full-scale operation, run a test seal on a sample package to verify settings and make any necessary adjustments.

Safety Precautions and Best Practices

Always adhere to safety protocols by wearing appropriate gear when handling machinery. Regularly inspect the device for irregularities and keep a clean working environment to prevent accidents.

Common Issues and Troubleshooting Tips

Inconsistent Sealing Quality

If you notice inconsistent seals, review and modify the temperature settings, as well as adjust the speed to better align with the material's properties.

Conveyor Belt Issues

Ensure proper alignment of the conveyor belt. Misalignment can often lead to inefficiency; periodic cleaning will also extend its lifespan.

Electrical Problems

Check the power supply connections and inspect internal components regularly. Replace damaged parts immediately to avoid malfunctions.

Maintenance and Care

Regular Cleaning Routines

Routine cleaning prevents buildup of residues that could compromise sealing quality. Use recommended solvents and follow guidelines strictly.

Lubrication and Parts Inspection

Apply lubricant to moving parts and conduct regular inspections to identify wear and tear early. This effort minimizes the risks of unexpected downtimes.

Periodic Professional Servicing

SCHEDULE professional servicing at intervals to ensure all mechanical and electrical systems are functioning optimally.

Storage Guidelines

If storing for extended periods, keep the FR-900 in a dry, dust-free environment, preferably covered to avoid exposure to elements.

Real-world Applications of the FR-900

Food Packaging Industry

The FR-900 excels in sealing snacks, dried fruits, powdered products, and other perishables, preserving freshness and extending shelf life.

Medical and Pharmaceutical Uses

Ideal for packaging medical supplies and pharmaceuticals, ensuring sterile conditions are maintained during storage and transport.

Industrial and Commercial Applications

Used extensively in sealing hardware, electronics, and various commercial products, demonstrating its robustness across different fields.

Tips and Tricks for Maximizing Efficiency

Optimizing Settings for Different Materials

By experimenting with different speed and temperature combinations, you can find the optimal settings tailored to specific materials, improving sealing strength and appearance.

Batch Processing Techniques

Organize packages in batches to streamline operations, significantly reducing handling times and increasing throughput.

Custom Modifications and Upgrades

Consider custom modifications like additional cooling fans or advanced sensors to enhance functionality and meet unique operational demands.

Integrating with Other Packaging Machinery

Maximize efficiency by incorporating the FR-900 into larger automated production lines paired with complementary machines like labelers and carton sealers.

Customer Reviews and Feedback

User Testimonials and Case Studies

Users consistently praise the FR-900 for its reliability and ease of use. Case studies demonstrate notable improvements in both small and large-scale packaging operations post-adoption.

Success Stories from Various Industries

Industries spanning from food processing to electronics report substantial gains in productivity and reduced waste due to the machine’s precision and efficiency.

Commonly Cited Advantages and Areas for Improvement

Frequent mentions highlight advantages such as minimal downtime and low learning curve. Some users suggest future iterations could benefit from enhanced portability.

Where to Buy and Additional Resources

Recommended Suppliers and Retailers

The FR-900 is available from authorized dealers and trusted online retailers, ensuring you receive genuine units backed by customer support.

Online Tutorials and Training Videos

Leverage detailed tutorials and videos accessible online to maximize the utility of your FR-900, covering everything from basic setups to advanced troubleshooting.

User Manuals and Technical Support Resources

Comprehensive user manuals accompanied by responsive tech support provide invaluable assistance and ensure continued smooth operation of your machine.